SGSO Technology Europe GmbH

COMPANY NAME:SGSO Technology Europe GmbH

HEADQUARTER: Krefeld NRW, GERMANY (Office & Stock)

ESTABLISHMENT: 01.Oct.2024

SEGMENTATION:Sales and Service

BRAND:SGSO

VISION:Keep advancing with European customers

Company Name:

SGSO Technology Europe GmbH

Headquarter:

Krefeld NRW, GERMANY

(Office/Warehouse/Technical Dept.)

Establishment:

01.Oct.2024

Segmentation:

Sales and Service

Brand:

SGSO

Vision:

Keep Advancing With Customers

for Stable Growth, Sustainable Optimization

Managing Director:

Gang HAN

Tax ID (Ust-idNr.):

DE 449662804

Commercial Register:

HRB 20703 Krefeld / Germany

SGSO Technogy Co.,Ltd.

Headquarter:

Taizhou, CHINA

Main Products:

solid and indexable end mills

Yearly Turnover:

21.1M USD (2023)

Employees:

218(Group 800+ )

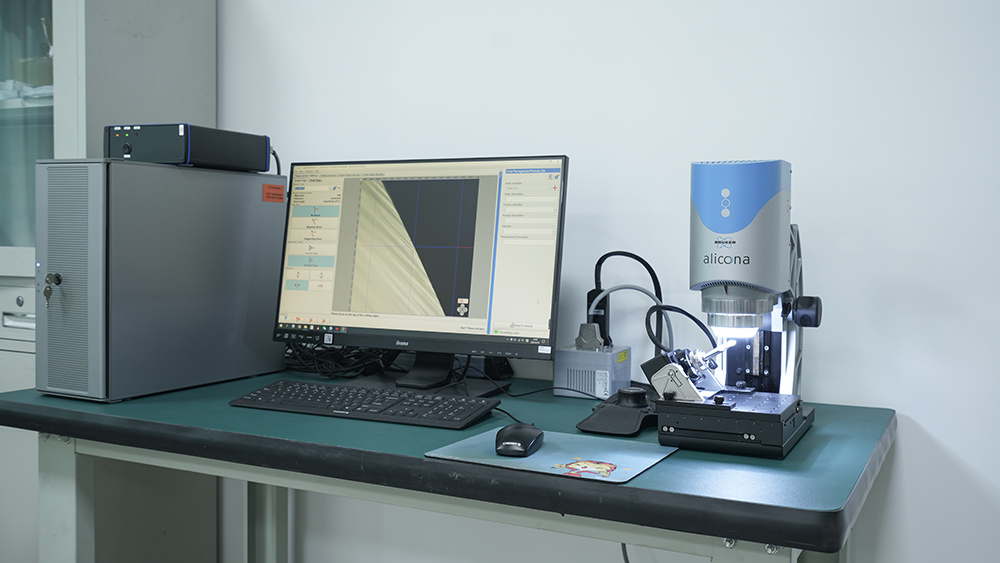

Grinding Machines:

40+(2024)

Yearly capacity:

2,000 K pcs (2024)

ISO Certificate:

lSO9000/ISO9001/ISO45001/ISO14001

Patents:

28 (2024)

Experienced R&D team

Factory area

Cooperative customers

History

KEEP ADVANCING WITH YOU

always with customers and for customers

for Stable Growth, Sustainable Optimization

COMPANY NAME:SGSO Technology Europe GmbH

HEADQUARTER: Krefeld NRW, GERMANY (Office & Stock)

ESTABLISHMENT: 01.Oct.2024

SEGMENTATION:Sales and Service

BRAND:SGSO

VISION:Keep advancing with European customers

心 Heart:

Integrity, Dedication, Perseverance

信 Trust:

Trust, Reliability, Confidence

新 Innovation:

Keep up with the times and welcome new ideas

鑫 Wealth:

Create wealth and success with customers

欣 Happiness:

Create joy and happiness for customers

INNOVATION

SGSO combines scientific and applied research, partnering with international research institutes to establish advanced coated tool research centers. These centers focus on areas such as materials, geometric design, grinding technology, surface treatment, nano-coatings, cutting applications, and high-efficiency machining solutions.

Grinding wheel selection. Dressing, runout, and dynamic balancing’s dealing.

Grinding oil selection. How to set the cooling and injection pressure.

Optimization of grinding processes and control of cutting-edge quality.

We choose the appropriate raw materials for carbide endmills based on factors such as the workpiece material, machine tool, and cutting conditions.

We offer the suitable tooling solutions based on our experience accumulated through our tests. We consider factors such as workpiece material, machine tool, and cutting conditions for customers.

We select the appropriate edge treating method based on the tool material, tool design, workpiece material, machine tool, cutting conditions, and the type of coating.

We are familiar with the different chemical element's combinations such as TiSiN, AlCrN, TiAlN, etc. We also know well of etching processes, bias, electric current, chamber pressure, gas flow rates, and the changes in cutting life and performance under different magnetic field.

We conduct tool testing, including various specifications and criteria, as well as identifying any issues. For improved tools, we evaluate factors such as tool cutting lifetime, processing quality, suitable processing data, applicable hardness, and types of workable materials.